Nothing but slim pickings left here. Almost everything was unbolted (or hammered off) from the lathe. Notice the tailstock under what remains of the lathe. It is too thick and compact to break with a hammer so I'll need to figure something out...

Here I've busted out a section of the lathe bed to break it roughly in half. Moving the thing as a single unit was not much of an option. I really had to wallop this thing with the sledge hammer quite a bit before it yielded. For awhile I was thinking I'd need thermite or something. But once an initial crack forms it's much easier from there. Click photo for larger view

Here is the broken lathe bed outside. The pieces on the bed are what I broke out of the middle.

I received a lot of feedback from this page but the following e-mail is my favorite of them;

"I was looking across the internet tonight at different metal working sites. I came across yours and almost puked! I am a machinist, and seeing you break up a working lathe disgusts me. Why reduce a machine meant to make precision parts into a pile of worthless scrap. I worked for 2 years to get my 1st lathe when I was only 15. It was way junkier than the one you destroyed. I loved the thing and used it every day. When it came time to upgrade, scrapping the thing NEVER came to mind. I would have rather given it away than scrap it. You took something from the great machine age, just to reduce it to poor iron age, rough parts. Do you sleep in a cave and kill your food with a club? Breaking up a machine tool is worse in my mind than barbarism. Shame on you!"

Notice how thick the "bed ways" section it. They break away from the thinner sidewalls of the bed forming "iron logs" of sort which I can barely break. I know that an oxy-acetylene flame can cut iron although not very well so I don't know if it'll cut this thickness of iron at all. I'd like to get my hands on one of those oxy-gasoline torches from either oPetrol or Petrogen and see if they'll work.

Here is the bed almost completely broken. The iron averages about 3/4" thick so before I started this I wasn't sure if I'd actually be able to break it apart. But when you yield the hammer like Thor then not much can stop it!

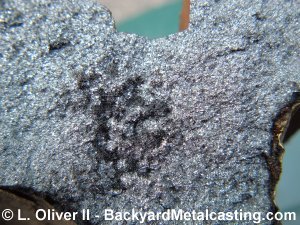

Here is an interesting look at the crystalline structure of the iron. Notice in the center of the casting there are darker iron crystals. It seems that this may indicate a different cooling rate. Perhaps this is a higher carbon concentration in the iron.

Believe it or not this is the broken up lathe bed in this wheelbarrel. It's nice how compact things can get when broken apart.

Here is my mountain of scrap iron that I keep hidden away near the garage. Truthfully calling it a "mountain" may be an exaggeration so let's call it a "hill of iron." In either case this is about 2500 pounds. Some of the stuff here is the metal lathe, a wood stove insert, a slip rolls machine, metal forming machine, a bunch of old pipe fittings, a pump mounting thing, drain pipes and other miscellaneous sources. Whenever I want to pour some iron I grab pieces as needed. I try to keep it as neat as possible but hey, it's a heap of iron... Click photo for larger view

Here is the tailstock along with some sections of the bed ways that broke away from the thinner sidewalls of the bed. I call them "logs." The tailstock is to thick and compact to break and the logs just take more effort than I want to put into it so I'll think of a sneaky way to get rid of them. The glove is for size comparison. Aside from considering the oxy-gasoline torch I'm thinking about a "scrap melter" furnace design where I can just drop the pieces in whole and molten metal drains out the bottom. Go to the Previous page or homepage